Whenever a training airplane fires up on the Embry-Riddle Daytona Beach Campus flight line, chances are good that its engine was assembled by one of the students in the aviation maintenance science (AMS) program. It sounds dicey—pilots-in-training relying on engines built by mechanics-in-training—but it’s been the Embry-Riddle way since 1956.

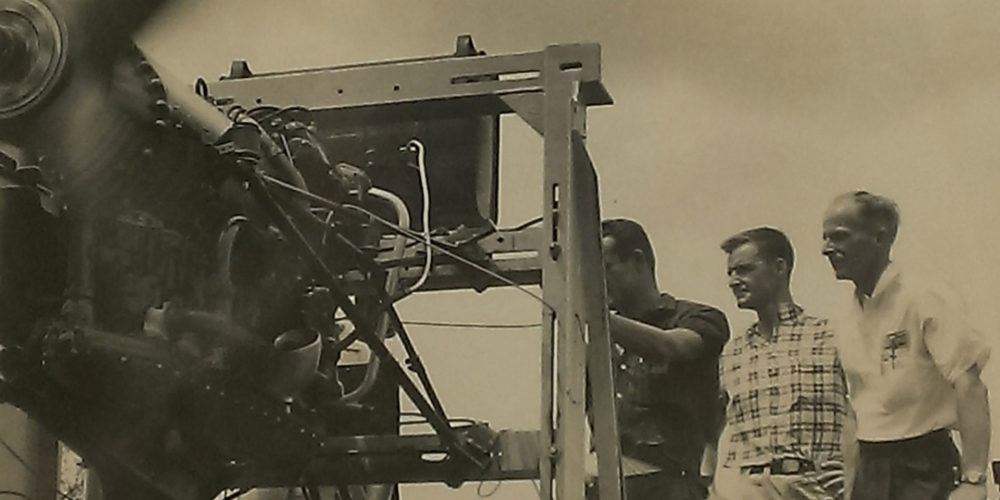

Embry-Riddle is the only school in the world where students work on piston-powered aircraft engines as non-certificated employees of a Federal Aviation Administration (FAA)-certificated engine repair station. The late Chandler Titus, professor emeritus and the university’s longest-serving employee (1953-2006), established the certificated repair station 60 years ago at Embry-Riddle’s then School of Aviation in Miami, Fla. Originally certified by the Civil Aeronautics Authority, the governing body that preceded the FAA, Titus’ primary goal was to improve training by giving students real-world experience, but the repair station also helped reduce the overhaul costs for the fleet.

University Archivist Kevin Montgomery says the applied learning put into practice by Titus was important in establishing the school as an institution of higher learning and worked to perpetuate the philosophy of its early founders. “Embry-Riddle’s co-founder John Paul Riddle believed that in order to be a proficient pilot, you had to understand your machinery. He was an aviation mechanic before he became a pilot, and all early flight students had to do their own maintenance as well,” Montgomery says.

Program Heyday

In the decades that followed, aviation maintenance science grew into the biggest academic program on campus. With Titus as the repair station manager, students would process 100 percent of the engines from the training fleet as well as all of the alternators, starters, magnetos and carburetors, says Roger Sonnenfeld (’86, DB), AMS repair station operations lead instructor and engine repair station manager at the Daytona Beach Campus.

“Work orders per year were in excess of a thousand. We used to have three sections of engine overhaul class, five days a week,” Sonnenfeld says. “They were staggered, so while one was in the classroom, the other was in the repair station.”

Today, students overhaul 15 to 20 engines annually from the training fleet, roughly 80 percent of the flight training department’s demand. The rest are sent to an outside repair company.

Eric Walterscheid, a current AMS student, says he and his peers spend many hours learning about engines before entering the repair station. “It was a little shocking, knowing that I’d be working on engines for the Cessnas and Diamonds that students would be flying. It gives me a sense that I need to perform very well. But with the supervision and guidance of our crew leader and inspector, I believe I’m very capable of working on airworthy engines.”

Safety First

Sonnenfeld is confident that the safety of Embry-Riddle’s nascent pilots and flight instructors is not compromised by the course, which is mandatory for the AMS degree. All of the work students perform is supervised by repair station inspectors—the repair station employs several. An inspector must sign off before engines or other components are returned to inventory for Embry-Riddle’s training fleet, just like at any other repair station.

The facility is regularly audited by a Flight Standards District Office (FSDO) inspector. “The FSDO inspector doesn’t cut us any slack just because they’re students,” Sonnenfeld assures. “They’re expected to perform at the same level as anyone in the field. We’ve never had an accident, fatality or any other incident with our aircraft due to an engine overhaul problem.”

Students who complete their airframe and powerplant certification and show exceptional skill can serve as crew leaders for the repair station, gaining valuable work experience while they complete their bachelor’s degrees. “Those students get snatched up pretty quick [by employers],” Sonnenfeld says.

Listen

The late Chandler Titus discusses the history of the aviation maintenance science program at Embry-Riddle in an oral history recorded in 2004 as part of the Embry-Riddle Heritage Project