Synthetic materials capable of shapeshifting from a solid to a liquid state — now under development at Embry-Riddle’s Research Park — might someday help building managers save on cooling costs and ease the burden on our nation’s aging electrical energy grid.

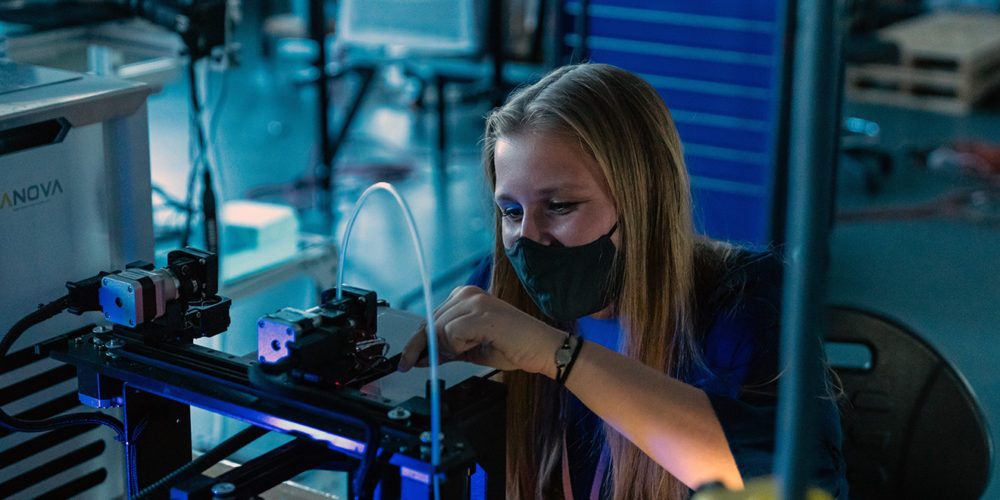

By leveraging simple desktop equipment to manufacture very thin strings of a special phase-changing material, Embry-Riddle researcher Sandra Boetcher and her team have opened the door to improved thermal energy storage on Earth and in space, too.

For the first time, the team has demonstrated that thermal energy storage composites can be printed using a 3D printer and fused-filament deposition process, says Boetcher, who is a professor of mechanical engineering and director of Embry-Riddle’s growing Thermal Science Laboratory.

The breakthrough, described in an article published by the journal Additive Manufacturing, involves encapsulating a phase-change material, or PCM, inside a skinny composite filament that stores heat. The fused filaments can then be 3D-printed to create heat-exchanging devices. When subjected to heat, Boetcher explains, solid-state PCMs absorb large amounts of heat as they change from one phase to another at a constant temperature. This characteristic makes them attractive for use in thermal energy storage tanks.

The research remains at an early stage, but prototype heat exchangers have been successfully fabricated. Associate Professor Rafael M. Rodriguez, a colleague of Boetcher’s, says it should be possible to scale up production for a wide range of applications. “Energy drives so many things,” he notes. “In the future, maybe we could take a 3D printer to the International Space Station, or even to Mars, to fabricate these types of heat exchangers and store energy more efficiently in space as well as on Earth.”